VFC301

FOUP and FOSB cleanerThe world’s only dedicated FOUP body and FOUP cover cleaner

VFC301 – The most technologically advanced worldwide FOUP and fosb cleaner

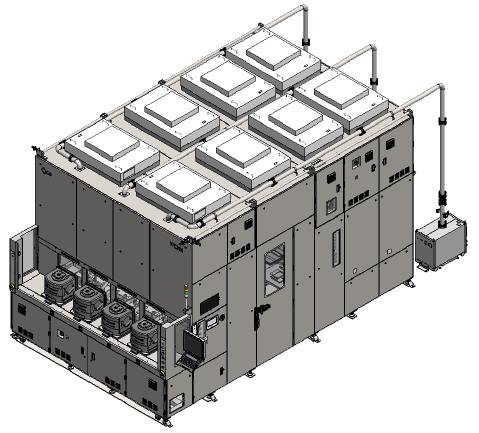

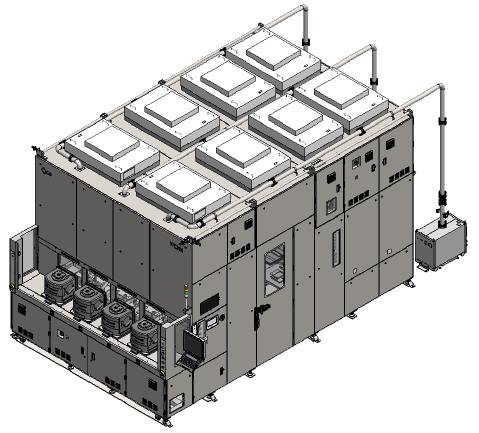

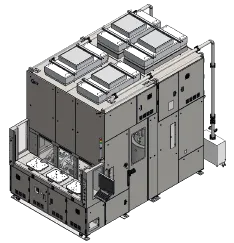

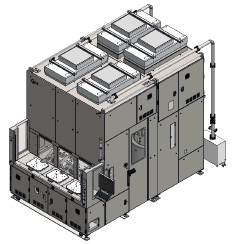

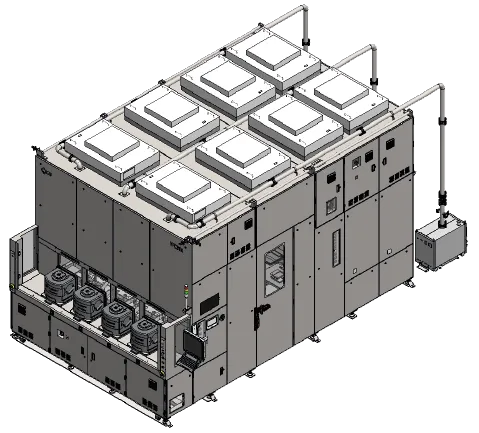

Discover the VFC301, a cutting-edge cleaning solution developed by Innovative System Technology, specifically designed for the semiconductor manufacturing industry. With its unique dual-chamber system, the VFC301 allows for the simultaneous cleaning of FOUP Bodies and Covers, optimizing operational efficiency and significantly reducing cycle times.

World’s N°1 for <30nm IC fabs and wafer/substrate manufacturers

Short delivery

time

6 month delivery

(4 months manufacturing included)

2 years

warranty

Minimum, from installation

date at your site

Historical

partnership

Samsung, HYNIX, SK Siltron

and more !

Friendly user

interface

Fast engineering

for software customization

impressive

reliability

Average of

4 alarms per year

want to know more ?

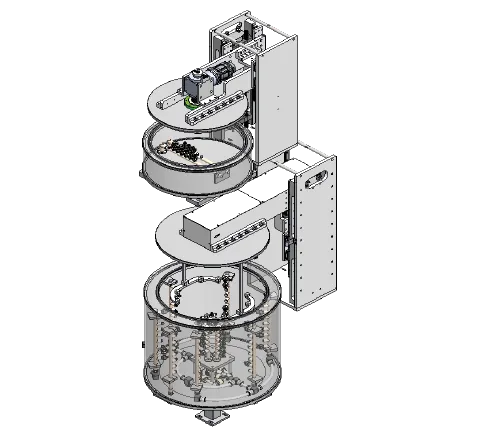

Vacuum dryer system (3set)

Remove outgassing and impurities •

Moisture reduction •

3 chamber •

Loader/unloader

N2 purge •

Leak check •

<5% humidity check •

Wafer presence sensor •

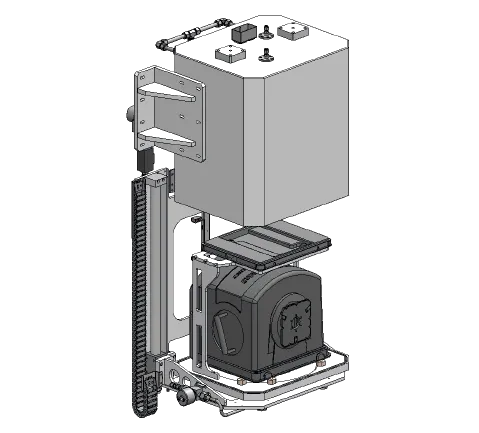

Tilt unit

FOUP transfer •

FOUP cover separation •

Loader/unloader

N2 purge •

Leak check •

<5% humidity check •

Wafer presence sensor •

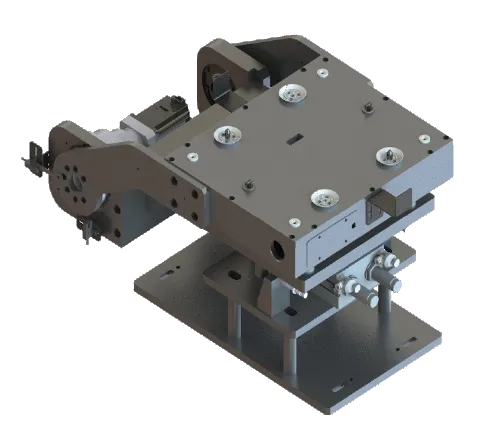

Loader/unloader

N2 purge •

Leak check •

<5% humidity check •

Wafer presence sensor •

Clean chamber unit

• Body and cover cleaning & drying

• 3 unit / chambers

• Hot & cold cleaning method

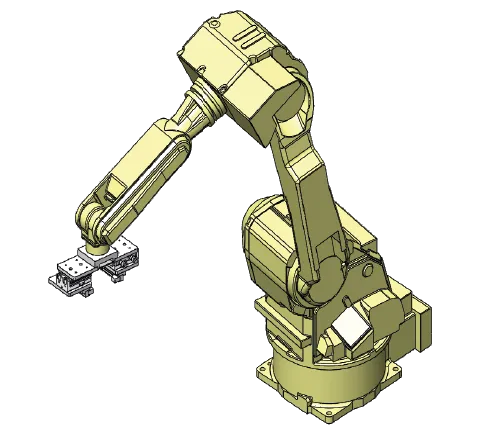

FOUP Transfer robot

• FOUP and cover transfer

• 6 Axis

• 20kg payload

boost your efficiency with the vfc301

key Features:

- High Productivity: The VFC301 can process up to 20 FOUPs per hour, ensuring maximum productivity in your manufacturing processes.

- Humidity Control: Maintains humidity levels below 5%, crucial for protecting sensitive semiconductor components.

- Advanced Cleaning Method: Achieving very low particle count by cleaning body and cover separatly. Utilizes hot and cold deionized water (DIW) to effectively remove particles, achieving a particle count of ≤ 200 (0.1 µm).

- Advanced in-FOUP wafer detection to prevent wafer scrap

Benefits and Features:

- N₂ Purge and Leak Check System: This system ensures the integrity of the cleaning process by purging the environment and checking for leaks, maintaining a contamination-free environment.

- Compact and Optimized Design: The VFC301‘s layout is specifically designed for space efficiency, fitting seamlessly into various manufacturing environments without compromising performance.

- Superior vacuum dryer to reach very low residual humidity and outgazing impurities

- Full AMHS compatibility

Unmatched Reliability:

- Mean Time Between Failures (MTBF): Greater than 1,500 hours, providing high reliability and fewer unexpected downtimes.

- Mean Time to Repair (MTTR): Less than 4 hours, enabling a quick recovery from operational issues.

- Alarm Frequency: An average of 0.31 alarms per month, reflecting consistent performance with minimal disruptions.

- Unmatched reliability : very low maintenance and cost of ownership (<2h every 6 months)

the system for your needs

NFC300

Specifications

| Item | NFC300 |

| Uptime | > 98% |

| Technology node | < 30nm |

| Throughput (/Hour) | 18 |

| Dimensions (WxDxH, mm) | 2.140 x 3.290 x 3.215 |

| Number of clean chambers | Body 2 chambers / Cover 2 chambers |

| Vacuum chambers | No |

| Vacuum pump | No |

| N2 Purge quantity | 1 |

| Halogen heater lamp | No |

| Humidity control | < 20% |

| FOUP leak tester | No |

| Loader / unloader | 2 Loader / 1 Unloader |

| Tilt & Opener | 3 |

| Robot | Four-axis robot |

| Hot D.I Unit | Optionnal |

| Controller & Monitor | 1 |

| FFU | 4 |

| CCD camera | 3 |

| Ionize | 2 |

| SEMI Standards | SEMI E87/E94/E40 |

| Host customer communication | GEM300 |

| OS | English Windows 10 |

VFC301

Specifications

| Item | VFC301 |

| Uptime | > 98% |

| Technology node | < 10nm |

| Throughput (/Hour) | 20 |

| Dimensions (WxDxH, mm) | 2.140 x 3.290 x 3.215 |

| Number of clean chambers | Body 2 chambers / Cover 2 chambers |

| Vacuum chambers | Yes (2) |

| Vacuum pump | Yes (2) |

| N2 Purge quantity | 3 |

| Halogen heater lamp | Yes |

| Humidity control | < 5% |

| FOUP leak tester | Yes (3) |

| Loader / unloader | 2 Loader / 1 Unloader |

| Tilt & Opener | 3 |

| Robot | Four-axis robot |

| Hot D.I Unit | Optionnal |

| Controller & Monitor | 1 |

| FFU | 4 |

| CCD camera | 3 |

| Ionize | 2 |

| SEMI Standards | SEMI E87/E94/E40 |

| Host customer communication | GEM300 |

| OS | English Windows 10 |

VFC310

Specifications

| Item | VFC310 |

| Uptime | > 98% |

| Technology node | < 10nm |

| Throughput (/Hour) | 30 |

| Dimensions (WxDxH, mm) | 3.000 x 4.800 x 3.120 |

| Number of clean chambers | Body 3 chambers / Cover 3 chambers |

| Vacuum chambers | Yes (3) |

| Vacuum pump | Yes (3) |

| N2 Purge quantity | 4 |

| Halogen heater lamp | Y |

| Humidity control | < 5% |

| FOUP leak tester | Yes |

| Loader / unloader | 2 Loader / 2 Unloader |

| Tilt & Opener | 4 |

| Robot | Six-axis multi-joint robot |

| Hot D.I Unit | Optionnal |

| Controller & Monitor | 1 |

| FFU | 8 |

| CCD camera | 3 |

| Ionize | 2 |

| SEMI Standards | SEMI E87/E94/E40 |

| Host customer communication | GEM300 |

| OS | English Windows 10 |